There are two primary methods of applying crystalline waterproofing. For new concrete structures, an integral waterproofing admixture is added directly to the concrete mix. This eliminates the need for a separate membrane or coating, ensuring the concrete itself is inherently water-resistant. For existing concrete surfaces, a cementitious, single-component crystalline waterproofing slurry is applied topically. Once cured, this forms a permanent waterproof barrier integrated with the substrate.In the following sections, we explore the key advantages and practical considerations of crystalline waterproofing systems in more detail.

What is Crystalline Waterproofing?

Crystalline waterproofing is an advanced concrete waterproofing technology that works by penetrating deep into the concrete matrix. Once applied, it reacts with moisture and unhydrated cement particles to form insoluble crystalline structures within the pores and capillary tracts of the concrete. These microscopic crystals effectively block water pathways, preventing the ingress of water under both positive and negative pressure.

Upon exposure to moisture, the active chemicals in the waterproofing material initiate a catalytic reaction, creating a permanent crystalline barrier that grows deeper into the concrete over time. This self-sealing capability not only enhances long-term durability but also ensures that future cracks and micro-fissures become sealed when exposed to water.

By filling the capillary voids and hairline cracks, crystalline waterproofing protects reinforced concrete from waterborne contaminants, chloride ion penetration, and corrosion of embedded steel reinforcement. The result is a highly durable, integral waterproofing system that becomes part of the concrete itself—ideal for below-grade foundations, water tanks, tunnels, and other demanding environments.

How Does Crystalline Waterproofing Work?

Crystalline waterproofing operates on a fundamentally different principle compared to conventional waterproofing methods. Traditional waterproofing systems typically rely on creating a surface barrier that blocks water from penetrating structural elements. However, crystalline technology works from within.

Unlike traditional systems, which generally aim to block water with an external barrier, crystalline waterproofing penetrates deep into the concrete substrate by utilizing the natural capillary network of the concrete. Upon contact with moisture, the active chemicals react with water and unhydrated cement particles to form insoluble crystalline structures. These crystals grow inside the capillaries and microcracks, effectively blocking water pathways and transforming the concrete into a self-sealing, water-impermeable mass.

This internal waterproofing mechanism not only prevents water ingress but also enhances the durability of the concrete by permanently filling voids. As a result, crystalline waterproofing is widely trusted for below-grade structures such as foundations, basements, water tanks, swimming pools, large aquariums, and even subway tunnels.

Advantages of Crystalline Waterproofing

Crystalline waterproofing meets expectations in insulation with its unique properties. In doing so, it also provides different advantages. The advantages it provides are as follows:

Deep Protection

Unlike conventional insulation applications, the material used here penetrates into the concrete over time. It provides in-depth protection by penetrating through the pores of the concrete. Water and moisture are definitively stopped by the application.

Increased Activity

What makes this method of insulation unique is the structure of the substances contained in it. When special minerals come into contact with water and moisture, they increase in volume and crystalline. With each leak, this process happens again and the crystalline minerals move into the concrete. Thus, waterproofing becomes much more effective. The level of impermeability becomes top level.

Crack Repair

The minerals, which increase in volume and become impermeable when in contact with water, fill the microcracks in the concrete. This process continues continuously, so that all cracks in the concrete are repaired by themselves.

Its crack repair feature makes insulation effective, prevents corrosion and increases the lifespan of structures. It is a distinct advantage that it does not contain chemicals that cause corrosion such as chlorine. In addition, it also provides long-term protection.

Chemical Resistance

It has high resistance to chemical substances. In areas such as houses and apartments, this feature is usually not noticeable. However, it is extremely important in industrial areas. This feature prevents chemicals from damaging both the insulation material and the concrete.

Environmentally Friendly

It contains no toxic and environmentally harmful substances. It also does not contain chemicals harmful to human health. It is a highly effective option for a sustainable solution.

Ease of Implementation

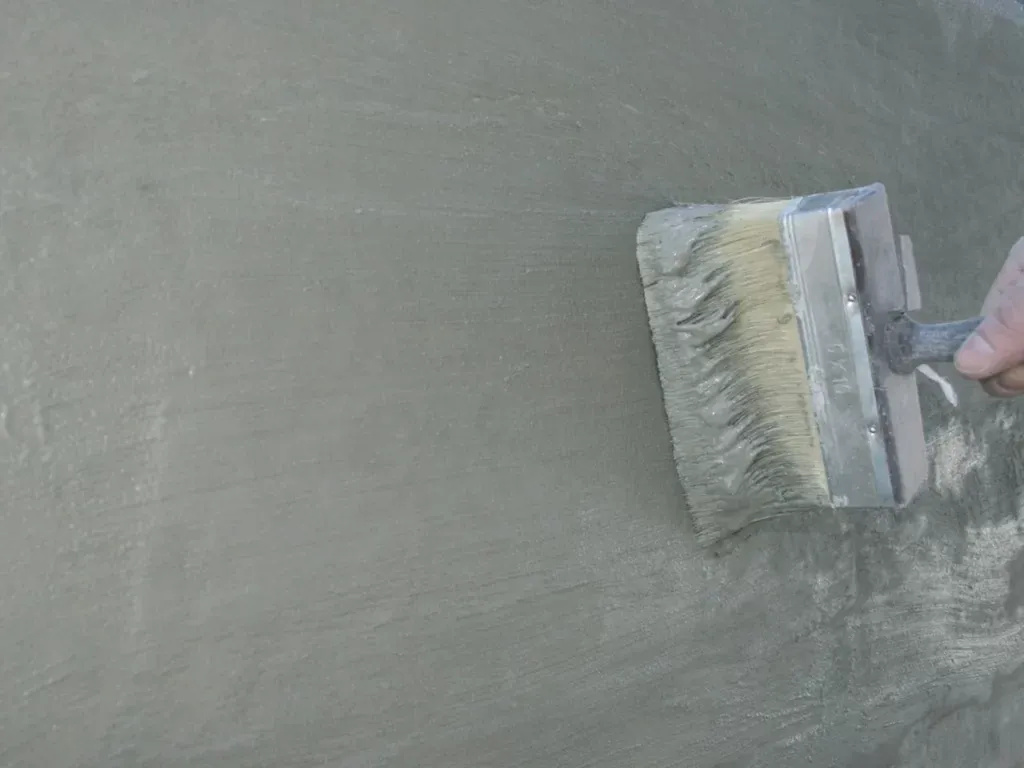

Crystalline waterproofing can be applied by adding directly to the mortar while the concrete is not yet ready. In this way, the concrete is automatically waterproofed. It provides insulation to existing concretes by applying the special mortar prepared with a trowel or similar tool.

It is extremely easy to apply and no extra equipment is required. Construction workers can apply it comfortably by following the instructions.

The advantages here may differ according to the preferred product.

How is Crystalline Waterproofing Applied?

There are different application forms of crystalline insulation. The first one is done with a crystalline impermeability admixture added to the concrete mix. The other is realized with insulation mortar. Details about these methods are as follows:

Crystalline Water Impermeability Additive

Additive products are available in liquid or solid form. The application of these additives is made according to the instructions of the preferred product. Again, the amount of additive varies between 2% and 15% depending on the product preference.

This admixture, which is added during the preparation of concrete, provides insulation properties to the prepared concrete. There is no extra work to be done afterwards. Concrete waterproofing admixture is one of the products used with this method. This product, which provides structural waterproofing, works in negative and positive directions. While it does not cause corrosion, it effectively fills capillary cracks. It can be used with all cement-based products.

Crystalline Waterproofing Mortar

Crystalline waterproofing material is a method applied for existing concrete to gain waterproofing properties. The steps followed for this method are as follows:

- Firstly, the application surface is cleaned and its soundness is checked. Deep cracks and weak points on the surface are repaired with repair mortar.

- After the surface is completely ready, mix the crystalline insulation mortar with an appropriate amount of water. The mixture is mixed for 3-5 minutes to obtain a homogeneous structure. Then, it is rested for about 2-3 minutes and mixed for 30 seconds for the last time and made ready for application.

- The mixture is applied to the surface in two coats. The first coat is applied in the same direction with the help of a trowel. The application is made by choosing one of the up and down or right and left direction options.

- After applying the first coat, wait between 3-12 hours and then apply the second coat. The second coat is applied in a different direction than the first coat. For example, if the first coat is applied up and down, the second coat is applied left and right. Thus, the coats are perpendicular to each other.

Where is Crystalline Waterproofing Used?

Crystalline waterproofing has a very wide range of uses. The places where it is widely used are as follows:

- Foundation and basement walls

- Swimming pools and concrete-based water tanks

- Metro tunnels

- Bridges

- Industrial structures requiring chemical and water resistance

- Elevator shafts

- Structures likely to be exposed to seawater

- Ground floors

- Curtain concretes

- Waste water and treatment plants

- Raft foundation

As can be seen, the area of use of this method is extremely wide. Its success is the most important reason for this situation.

Negative Direction Crystalline Waterproofing

Insulation is divided into negative and positive insulation. The positive direction is the insulation applied to the surfaces where moisture comes from. The negative one is the applications made from the opposite side, not from the direction where the moisture comes from. Examples of negative applications are the insulation applied to the interior walls of houses.

The crystalline method is extremely successful in positive and negative applications. But in negative directional insulation, it is almost unrivaled. When applied negatively with other materials, moisture penetrates into the wall and this cannot be prevented. But with the crystalline method, as the moisture comes into the wall from the outside, the minerals applied crystalline. Each time they go deeper and keep the moisture out. Because of these features, it would not be wrong to say that they are much more preferred in negative insulation. You can examine the products in the relevant category of our site to make crystalline waterproofing.